As people's requirements for environmental protection and building quality continue to increase, many high-efficiency admixtures with excellent technical performance, superior product quality, wide range of use, strong adaptability and obvious economic benefits have emerged. Dry-mixed mortar admixtures can not only improve the workability, water retention, strength and other properties of mortar, but also have important significance for saving the cost of building cementitious materials, reducing energy consumption and ensuring project quality.

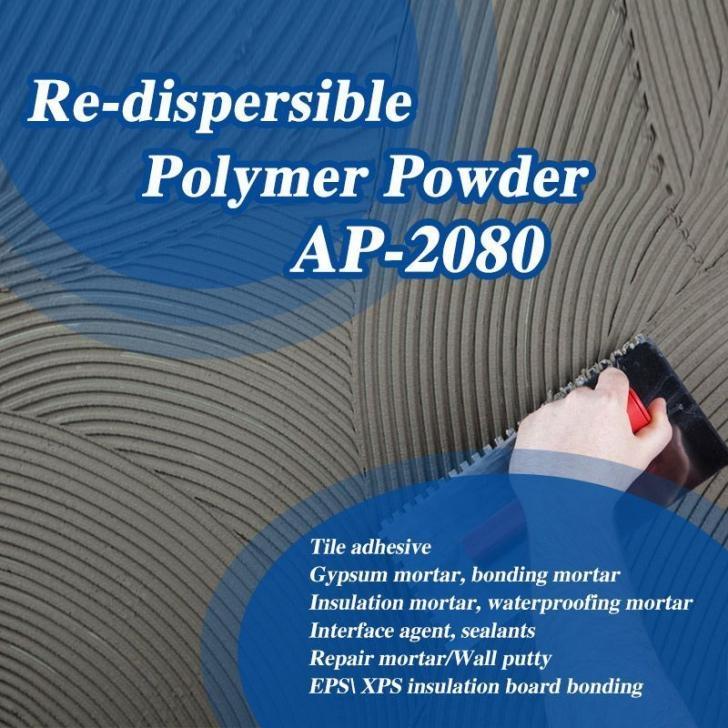

Redispersible polymer powder has good effects in thin-layer plaster mortar, tile adhesive, exterior wall insulation system, self-leveling floor materials and other materials. Redispersible polymer powder is used as the second binder in mortar, complementing the inorganic binder cement, so that the bonding performance of mortar is improved; after adding redispersible polymer powder to dry-mixed mortar, the workability of mortar is greatly improved; after adding redispersible polymer powder, the folding and compression ratios and tension-compression ratios of mortar are greatly improved; latex powder increases the dry apparent density of mortar with the increase of latex powder dosage, and the modified mortar has certain wear resistance and impermeability.

The hardening of cement and gypsum is due to their hydration, but when the mortar is applied in a thin layer, water quickly penetrates into the matrix or evaporates. Cellulose ether has good water retention capacity due to the intermolecular force (van der Waals force); it can also ensure the uniformity and completeness of the hydration of inorganic binders, because it has roughly the same evaporation heat and capillary diffusion as water. Mortar is a non-homogeneous system, in which water and aqueous solution are continuous phases. When water is first added, it greatly increases the friction and movement resistance, making it difficult to apply mortar, especially in thin layers. The addition of cellulose ether plasticizers can lubricate the mortar and change the workability of the mortar, which can prevent the risk of cracking when thick layers are applied. In addition, the volume of cellulose ether dissolved in the liquid phase of the mortar slurry expands and increases the viscosity of the slurry due to the bridging effect, which is of great significance in preventing the sinking of fine aggregates in cement slurry and the sinking of cement particles in water dispersion (i.e. stratification), improving the workability and uniformity of the mortar, increasing the bonding strength between the mortar and the matrix material, and reducing shrinkage.

Water reducer has a good plasticizing effect. The basic function of water reducer is to reduce the water demand of mortar. It can significantly reduce the water demand while obtaining the same workability. The reduction increases with the increase of water reducer dosage. Due to the dispersing effect and certain air entraining effect of water reducer, the mortar with water reducer also has a certain improvement in the water retention of mortar. Water reducer is often used in mortars that need to have good self-leveling properties, such as self-leveling cushion, surface mortar or leveling mortar. There are three main types of dry-mix mortar: casein, melamine formaldehyde condensate, and polycarboxylic acid. Casein is a superplasticizer with excellent performance, especially for thin-layer mortar, but because it is a natural product, the quality and price often fluctuate. Melamine formaldehyde condensate is a superplasticizer with good performance, but it has limited effect on thin-layer mortar and releases formaldehyde. Polycarboxylic acid is the latest technology developed, with high efficiency and no formaldehyde release.

Organosilane compounds and their modified compounds have active reactive groups. In the highly alkaline environment after cement hydration, the hydrophilic organic functional groups in silane hydrolyze to form highly reactive silanol groups. The silanol groups continue to react irreversibly with the hydroxyl groups in the cement hydration products to form chemical bonds, so that the silanes connected together by cross-linking are firmly fixed on the surface of the pore wall in the cement mortar. Because the hydrophobic organic functional groups face the outside of the pore wall, the surface of the pore acquires hydrophobicity, thereby bringing an overall hydrophobic effect to the mortar.

Because the addition of finely dispersed organic polymers will increase the porosity of the mortar, a defoamer must be introduced at the same time to eliminate bubbles. Powdered defoamers are based on different chemical groups, including hydrocarbons adsorbed on inorganic carriers, stearic acid and its esters, tributyl phosphate, polyethylene glycol or polysiloxane. At present, the powdered defoamers used in dry-mixed mortar are mainly polyols and polysiloxanes. In addition to adjusting the bubble content, the application of defoamers can also reduce shrinkage. A good defoamer must have good chemical stability, lower surface tension than the defoamed medium, and insoluble in the defoamed medium. Defoaming effect may produce air entrainment in another system. Therefore, the most effective defoamer or composite defoamer should be selected for different systems.

Longou provide one stop solution for cutomers in construction industry. With three production bases, our products are with high quality and cost-effective at the same time. Welcome to contact us for more details! Email: coco@longoucell.com Whatsapp: +86 17603895865

Post time: May-21-2025