Cellulose ether is the main additive in ready-mixed mortar. The types and structural characteristics of cellulose ether are introduced. The effects of hypromellose ether HPMC on the properties of mortar are systematically studied. The results show that HPMC can improve the water-holding property of mortar, reduce the water content, reduce the density of mortar mixture, prolong the setting time, and reduce the flexural and compressive strength of mortar. Mortar is one of the most widely used materials in the construction industry. With the development of materials science and the demand of construction quality, mortar has become as popular as ready-mixed concrete, it has been gradually commercialized. Compared with the mortar prepared by traditional technology, the commercial production of mortar has many advantages: 1, high product quality; 2, high product efficiency; 3, less environmental pollution, convenient for civilized construction, at present, there are Guangzhou, Shanghai, Beijing and other cities to promote ready-mixed mortar, related industry standards, standards and national standards have been issued or will be issued soon. A big difference between ready-mixed mortar and traditional mortar is the addition of chemical admixture, of which cellulose ether is the commonly used chemical admixture. Cellulose ether is usually used as a water-retaining agent to improve the Operability of ready-mixed mortar. Therefore, it is helpful to select and use cellulose ether correctly and to ensure the stability of the performance of cement mortar by further understanding the influence of cellulose ether’s type and structure characteristics on the performance of cement mortar.

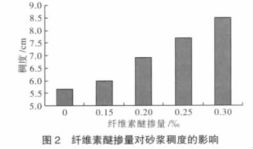

1. The species and structure of cellulose ether cellulose ether is a kind of water-soluble polymer material, it is made of natural cellulose by alkali solution, grafting reaction (etherification) , washing, drying, grinding and other processes. Cellulose ethers are classified into ionic and non-ionic types. Ionic cellulose has carboxymethyl cellulose salts, while non-ionic cellulose has hydroxyethyl cellulose ethers, hydroxypropyl methyl cellulose ethers, Methyl cellulose ethers, etc. . Because ionic cellulose ether (carboxymethyl cellulose) is unstable in the presence of calcium ions, it is rarely used in dry powder products with cementitious materials such as cement and hydrated lime, the cellulose ethers used in dry mortar are mainly hydroxyethyl methyl cellulose ethers (HEMC) and hydroxypropyl methyl cellulose ethers (HPMC) , their market share exceeds 90% 2. The effect of cellulose ether on the properties of cement mortars 1. The raw material cellulose ether for testing: produced by Shandong Gomez Chemical Co. , Ltd. , viscosity: 75000; Cement: 32.5 grade composite cement; Sand: medium sand; Fly Ash: II grade. 2 test results 1. The water-reducing effect of cellulose ether figure 2 is the relationship between the consistency of mortar and the content of cellulose ether in the same mix proportion, gradually increased. When 0.3‰ is added, the consistency of the mortar is increased by about 50% , which shows that cellulose ether can improve the workability of the mortar, with the increase of the content of cellulose ether, the amount of water used can be reduced gradually. It can be considered that cellulose ether has a certain water-reducing effect. 2. Water-holding mortar water-holding mortar refers to the ability of mortar to hold water, and is also a performance index to measure the stability of fresh cement mortar during transportation and parking. The water retention of ready-mixed mortar can be measured by the index of Delamination and water retention, but it is not sensitive enough to reflect the difference because of adding water retention agent. The water retention test is to calculate the water retention rate by measuring the quality change of the filter paper before and after contact with the specified area of mortar in a certain period of time. Because of the good water absorption of filter paper, even if the water retention of mortar is very high, filter paper can still absorb the water of mortar, so the water retention rate can accurately reflect the water retention of mortar, the higher the water retention rate, the better the water retention.

Post time: Oct-30-2023