As an economical, easy to prepare and process building material, concrete has excellent physical and mechanical properties, durability, practicality and reliability, and is widely used in civil construction. However, it is unavoidable that if only cement, sand, stone and water are mixed, then the result is ordinary concrete, whose appearance tone is not so pleasing, and it is easy to ash and return salt. Therefore, the indoor concrete floor is usually covered with carpet, vinyl or tile and other covering materials, and the wall is mostly used as a decorative layer, tile or finishing mortar, wallpaper.

Today, concrete art mortar surface decoration process has become one of the highly respected concrete surface art means in North America and Australia. This originated in the 1950s concrete surface stamping process (stampedconcrete), that is, the surface of fresh concrete is sprayed with a color hardener, by the use of pattern molds and release agents, the concrete surface to simulate the texture pattern of natural forms, such as granite, marble, SLATE, pebble or wood texture texture. To meet people's needs for decorative effects of natural materials. This technology is not only suitable for fresh concrete, but also suitable for the renovation of existing concrete surface, such as the courtyard of the home, garden channels, driveways, swimming pools to the ground of shopping malls and hotels. The decorative effect of this so-called art mortar surface layer has natural fidelity and uniqueness, which can renew the dull appearance of concrete, but also set decorative and functional in one, which not only has the economy, durability and practicality of concrete, but also organically combines aesthetics and creativity.

In contrast, the life expectancy of common concrete substrates far exceeds that of commonly used cladding materials, while carpeting and vinyl materials are prone to tear, stick and wear, as well as water contamination, and these floor materials need to be replaced every few years. The art mortar surface is as durable as concrete, hygienic and easy to maintain, and its decorative effect can be easily matched with the surrounding architectural style and integrated into the surrounding scenery. Unlike carpet or vinyl veneer materials, art surface mortar is not easily damaged by tearing, sticking, abrasion or water overflow; There are no fibers or cracks to hide dust or allergens, and they are easy to clean or flush with minimal maintenance. Compared with the process of imprinting patterns on the new concrete surface, the art mortar surface layer process is simpler, faster and more economical.

ADHES redispersible emulsion powder - the key component of artistic surface mortars

Different from the traditional ordinary coating mortar, the concrete art coating mortar must contain organic polymer in addition to pigments, and this mortar is what we call polymer modified dry mix mortar. The polymer-modified cement-based surface material is composed of cement, aggregate, pigment, ADHES redispersible emulsion powder and other additives, and can meet various performance requirements of constructability and hardening well by adjusting the formula.

Polymer modified cement-based surface materials were introduced into commercial floor engineering in the 1980s, initially as thin layer repair materials for concrete surfaces. Today's art surface mortar can not only be applied to the floor decoration of various occasions, but also suitable for the decoration of walls. The polymer modified art surface mortar can be coated very thin, its thickness can be the maximum particle size of the sand, or the thickness of tens of millimeters without worrying about peeling, cracking, more importantly, the polymer modified surface layer has a stronger resistance to salt, aggressive substances, ultraviolet light, harsh weather conditions and traffic wear caused by the damage ability.

Art surface mortar contains ADHES redispersible emulsion powder, whose high adhesion can ensure the solid bond between the surface material and the concrete substrate, and give art mortar good bending strength and flexibility, which can better withstand dynamic loads without being damaged. Moreover, the surface layer of mortar can better absorb the internal stress generated by the change of ambient temperature and humidity in the interior of the material and the interface, so as to avoid cracking and spalling of the surface layer mortar. If ADHES redispersible emulsion powder with hydrophobic properties is used, the water absorption of the surface mortar can also be significantly reduced, thus reducing the intrusion of harmful salts on the decorative effect of the surface mortar and the damage to the durability of the mortar.

ADHES modified art surface mortar construction

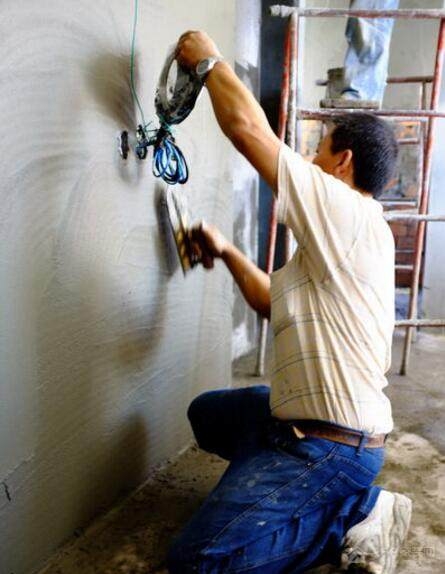

Art mortar used on existing concrete surfaces should first be degreased and pickled. If there are other surface materials on the concrete such as coatings, tile mosaics, adhesives, etc., these materials must be removed by mechanical methods to ensure that the art mortar surface can be mechanically/chemically firmly bonded to the concrete substrate. For the crack part, it should be repaired in advance, and the position of the existing expansion joint must be retained. After the basic treatment, the art mortar surface can be constructed according to the relevant steps.

Art mortar surface lamination process

The surface with the same decorative effect as the traditional embossing concrete process can be obtained by using the embossing process. First, use a scraper or trowel to coat the interface layer of the polymer modified cement material as thinly as possible, and the thickness is the maximum particle size of the sand. When the putty layer is still wet, a colored art mortar of about 10mm thickness is spread with a marker harrow, the harrow marks are removed with a trowel, and the textured pattern is imprinted with the same impression as the traditional embossed concrete. After the surface is dry and solid, the sealant with pigment is sprayed. The sealant liquid will bring the color to the low-lying areas to produce a primitive style. Once the bumps are dry enough to walk, two coats of acrylic transparent finish sealant can be applied over them. Outdoor recommended use of anti-slip cover sealant, after the first sealant dry, and then construction of anti-slip coating, usually the surface can be pressed 24 hours after maintenance, 72 hours can be opened to traffic.

Art mortar surface coating process

Thickness of approximately 1.5-3 mm, suitable for indoor and outdoor applications. The construction of the colored putty layer is the same as above. After the putty layer is dry, the paper tape is randomly pasted on the putty layer to form a pattern, or the paper hollow pattern such as stone, brick, tile is laid, and then the colored art mortar is sprayed on the putty layer with an air compressor and a funnel spray gun, and the colored mortar material sprayed on the putty is smoothed or overpowered with a trowel. This creates a colorful, flat, or skid-resistant decorative surface. In order to create a natural and realistic effect, the dry surface of the mortar can be gently wiped with a sponge stained with color paste. After a large area of wiping is finished, repeat the above practice to deepen the color or locally strengthen the color. Several colors can be selected according to the needs, once the color is highlighted and strengthened, let the surface dry properly, remove the tape or paper hollow pattern, clean the surface, and apply the appropriate sealant.

Art mortar surface layer self-leveling dyeing process

At this stage, the self-leveling art mortar surface is mainly used in the interior, usually through dyeing to form patterns, often used in commercial places such as automobile exhibition floor, hotel lobby and shopping malls, theme parks, but also suitable for office buildings, residential heating floor. The design thickness of the polymer modified self-leveling art mortar surface layer is about 10mm. Like the self-leveling floor mortar construction, at least two styrene acrylic emulsion interface agents are first applied to close the pores on the concrete substrate, reduce its water absorption rate, and increase the adhesion between the self-leveling mortar and the concrete substrate. Then, the self-leveling mortar surface layer is spread and air bubbles are removed by using an air vent roller. When the self-leveling mortar has hardened to a certain extent, the relevant tools can be used to carve or cut the pattern according to the design and imagination on it, so that the decorative effect that can not be obtained with other decorative materials such as carpets and tiles can not be obtained, and it is more economical. Patterns, art designs and even company logos can be used on self-levelling surfaces, sometimes in combination with cracks in the substrate concrete or artistic conceals of the parts that cause cracks in the surfaces. Color can be obtained by prior addition of pigments to dry-mixed self-levelling mortar, and more often by post-dyeing treatment, specially formulated colorants are able to react chemically with lime components in the mortar, which slightly etch and fix the color in the surface layer. Finally, the coating sealing protectant is applied.

Finishing sealant and polish

Finishing sealants and finishes are the final step in all decorative layers used to seal, wear and waterproof art mortar surfaces, ranging from high-volume industrial sealants for outdoor use to polishables for indoor use. Choosing a sealant or wax that matches the color of the art mortar finish can enhance the tone and add luster, and clear coatings can show antique flavor and luster or make chemical coloring show mottled traces. Depending on the volume of traffic in the floor application, the sealant or wax can be reapplied periodically, but maintenance can be carried out infrequently as with the floor wax. In order to avoid damage to the art mortar surface and traffic wear, if the traffic flow on the ground is high, the sealing protective agent can be applied several times. Regular maintenance can well maintain the decorative effect of the surface layer, and greatly extend its service life.

Costs and limitations

The average cost of a concrete art mortar surface is usually 1/3-1/2 higher than that of a natural block material such as SLATE or granite. Hard floor materials such as tile, granite or decorative concrete may not be attractive to consumers who prefer soft materials such as carpets or soft vinyl materials. Defects may lie in the heat sensation underfoot, the scattering of sound and the possibility of falling objects breaking, or the safety of a child who may crawl or fall on the ground. Many people are willing to lay small rugs on hard floors or long rugs in walkways and areas to add beauty, but the choice of these items should be included in the budget.

As one of the effective means to beautify concrete, art surface mortar is relatively simple, economical and durable, easy to maintain, and is the best embodiment of aesthetics and creativity.

Post time: Feb-23-2024